Transforming Ideas into Practical Digital Solutions

Helping your team work smarter, move faster, and discover new opportunities.

With over twenty-five years experience in the automotive industry, manufacturing, engineering, and software development, I understand what matters in real-world operations, speaking the same language as everyone from machine operators to executives, and turning complex challenges into clear, effective digital tools.

My approach is straightforward: listen, collaborate, and deliver results. Whether you want to automate a process, put your data to work, or try new digital tools, I help you turn ideas into real solutions step by step.

Strategic Pillars

Human Judgment First

Digital tools are only valuable when guided by human expertise. I help clients leverage technology where it truly matters, always keeping human judgment, responsibility, and decision-making at the center.

Transversality

I understand priorities across all levels from the shop floor to engineering and IT, designing solutions that bridge teams and anticipate challenges before they arise.

Ethics & Value

Transparency, confidentiality, and long-term value are core to my work. I focus on lasting results and real impact, not quick fixes or billable hours.

Continuous Improvement

Progress comes from learning and adapting together. I share knowledge, build on what works, and refine solutions over time so every project strengthens your team for future challenges.

Practical Innovation

I’m passionate about technologies like 3D visualization, digital twins, AI, and ML, but always as practical tools to solve real problems, never just to follow trends.

Collaboration & Co-Creation

The best solutions are built together. I work closely with clients, combining your expertise with my technical know-how.

Adaptability & Flexibility

No two projects are alike. I adapt my methods and communication style to fit your needs never a one-size-fits-all approach.

International & Multicultural Perspective

Over the past two decades, I’ve built my career across Brazil, Portugal, Germany, and Romania. Each country has shaped how I approach challenges, work with teams, and find practical solutions in different business cultures.

This international path has taught me to adapt quickly, stay curious, and respect diverse perspectives.

I work easily with teams from the shop floor to executives, and thrive in global environments where many languages and backgrounds come together to get things done.

Professional Journey

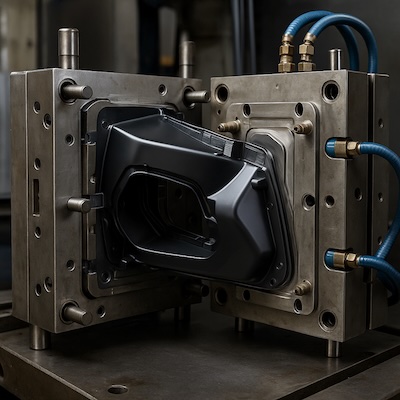

1998–1999

Apprentice, Mold Design

Pro Model Modelações Ltda

São Bernardo do Campo - Brazil

Gained foundational skills in plastic injection mold design and 3D modeling through hands-on experience.

1999–2001

Industrial Apprentice & Technical Lead

Geco Moldes Lda

Maceira Liz - Portugal / Diadema - Brazil

- Completed a full-cycle apprenticeship in CNC, CAM, and mold/toolmaking in Portugal

- Returned to Brazil to help launch a new branch, lead a CNC team, deliver technical training and implementation support

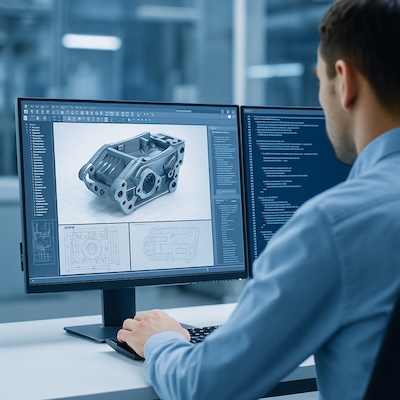

2001–2005

CAD/CAM Programmer

Karmann Ghia do Brasil Ltda

São Bernardo do Campo - Brazil

- Programmed large multi axis CNC milling for automotive stamping dies and automated workflows using Office/VBA.

- Co-developed an early AI system for machining time prediction.

- Co-developed infrastructure for ABB robotic milling of styrofoam models (EPS) used in metal casting for stamping tools.

- Self-taught CATIA V5 to drive manufacturing engineering innovation.

2005–2006

CATIA V5 Instructor & Trainer

PLM Expert Ltda

São Paulo - Brazil

Delivered CATIA V5 training to engineers at leading firms, building strong skills in communication and technical education.

2007–2008

Technical Documenter (Body-in-White)

PSA Peugeot Citroën S/A

São Paulo - Brazil

Standardized documentation, managed global systems, and developed tools for KPI tracking and process improvement using CATIA, PLM systems, SAP, and other platforms.

2008–2010

CATIA V5 Specialist, Tooling Designer

Karmann Ghia do Brasil Ltda

São Bernardo do Campo - Brazil

- Designed tooling, jigs, and fixtures.

- Implemented advanced CATIA automation for aluminum wheel mold design, accelerating the development process.

2010–2018

Body in White Designer & Technical Leader (Body-in-White)

Renault do Brasil S/A

São José dos Pinhais - Brasil / Bucharest - Romania

- Developed product designs for BIW parts in Brazil and Romania.

- Led launches, troubleshooting, and cross-functional work in pre-series projects.

- Developed and optimized production processes for Body-in-White assemblies.

2018–2019

CNC Coordinator & Product Designer

Benno Burghaus GmbH

Solingen - Germany

Coordinated CNC production and designed forging dies, jigs, fixtures, and products for fine cutlery, implementing solutions to enhance quality and productivity.

2019–2021

Product Design & Digital Solutions Consultant

Independent

Solingen - Germany

Transitioned to digital solutions, providing web applications and industrial design services including product and manufacturing design for a range of clients.

2021–2024

Full-Stack Developer

Nuromedia GmbH

Cologne - Germany

- Contributed to the development of a digital healthcare platform for Parkinson’s care

- Collaborated on 3D dashboards to visualize data from smart prosthetics

- Helped build AI-powered hospital dashboards using FHIR and 3D digital twin visualizations

- Supported real-time energy monitoring applications with dashboards & geospatial map

2024–Present

Digital Twins, Integration & Industry 4.0 Consulting

Independent

EU / Latam (Remote)

Advanced pre-sales study for an AI-ready digital twin datacenter project in Brazil. Developed standardized components and reusable app skeletons to speed up future development and delivery.